Big building projects don’t always need to take years or bust budgets. Modular jails are proving that speed, safety, and strength can come in a streamlined package. Behind these efficient facilities are experienced detention equipment contractors who know how to deliver secure solutions that work now—and for years to come.

Accelerated Timelines Through Offsite Fabrication

Modular jails are built faster not because corners are cut, but because construction happens in a controlled space before hitting the ground on-site. The modules are pre-made, inspected, and assembled while site prep happens at the same time. That cuts weeks, even months, off the project timeline. Delays caused by weather or site logistics? Not a problem.

Detention equipment contractors understand the urgency many jurisdictions face. Whether it’s replacing outdated facilities or adding more beds quickly, time matters. Offsite fabrication keeps quality high and momentum steady, which means faster delivery without sacrificing safety or function. Facilities can be operational sooner—with fewer surprises during the build.

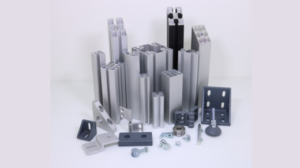

Precision Engineering for Tight Security Protocols

Security isn’t negotiable in jail design. Every door, wall, and hinge needs to meet strict standards—and that’s where modular really shines. These facilities are built to exact specifications using precision tools that leave no room for error. From steel reinforcements to tamper-proof locks, every component is engineered with purpose.

A seasoned security detention equipment contractor knows how to integrate these high-level features directly into each unit. This approach minimizes gaps and weak points, making escapes and breaches much less likely. It’s not just about fitting parts together—it’s about locking down an environment that meets federal and local codes without compromise.

Scalable Layouts That Evolve With Facility Needs

Modular doesn’t mean fixed. These systems are designed to grow or shift based on changing demands. If a facility suddenly needs to increase capacity or add new functions like medical units or isolation cells, additional modules can be connected with ease. The original structure doesn’t need to be torn down—just expanded.

This kind of flexibility gives administrators the breathing room to plan for the future. With input from detention equipment contractors, they can design a system that not only fits their current population but also adapts over time. Need to relocate or reconfigure? That’s built into the design. It’s smart planning without the heavy lifting.

Reduced On-Site Disruption During Installation

Traditional construction can disrupt daily life around the job site. Dust, noise, equipment, and long-term crews affect everyone from staff to nearby communities. Modular jails cut that chaos by keeping most of the work offsite. The installation process is shorter, cleaner, and easier to manage.

That’s a major win for detention facilities that need to stay secure while expanding or upgrading. Detention equipment contractors plan each stage carefully to avoid interfering with existing operations. There’s less risk, less downtime, and a smoother transition into service. Quietly building security where it’s needed most—that’s what modular makes possible.

Integrated Systems Designed for Long-Term Durability

It’s not enough for a jail to look sturdy—it needs to stay that way for decades. Modular systems are built with longevity in mind, using reinforced materials and standardized parts that hold up under constant use. Plumbing, HVAC, and electrical systems are integrated right into the modules and tested before delivery.

What sets this apart is how the infrastructure is designed to work as a complete unit. There’s no patching things together after the fact. Security detention equipment contractors oversee the process from the design table to installation, ensuring that each part plays a role in the long-term performance of the entire facility. It means less upkeep, fewer breakdowns, and a better return on investment.

Streamlined Maintenance With Accessible Infrastructure

Maintenance crews don’t want to tear through walls to reach a busted pipe or faulty wire. Modular jail units make access straightforward. The design includes built-in service routes that let teams get to what they need without disrupting the entire block or moving inmates around.

This thoughtful layout is no accident. It’s the result of collaboration between facility planners and experienced detention equipment contractors who’ve worked inside real-world detention settings. With easy access points and clearly marked systems, maintenance gets done faster—and safer. That means fewer outages, smoother daily operations, and less wear on staff resources.

Cost Predictability Through Standardized Fabrication Methods

One of the hardest parts of public construction is staying on budget. Costs add up fast, especially with on-site surprises. Modular systems shift the bulk of the work into a repeatable, factory-controlled process. That means clearer pricing from day one and fewer unexpected expenses down the road.

By working with a security detention equipment contractor, facility managers can lock in material costs and timelines early. Standardized fabrication reduces waste and increases efficiency, which keeps projects on target. That financial stability allows administrators to focus on performance instead of paperwork—delivering secure, reliable solutions without budget bloat.

+ There are no comments

Add yours